Oracle Inventory – Material Workbench

How to view on-hand quantity for an Item

Material Workbench:

Material Workbench is used to check

1. Item availability in the Organization.

2. Availability can be under different status such as On Hand Quantity, Available to Reserve and Available to Transact.

3. In-receiving, on-hand quantities, and in-transit material across the organizations.

Search through Query:

This is used in-case of frequent search of on-hand quantity with certain search criteria.

Optionally enter a query name and select appropriate options and save the Query.

‘Public’ – Checkbox enabled indicates whether all users can be use this query. If the checkbox is enabled, the query is not public & only the user who created can use it.

Material Workbench: Viewing On-Hand Quantities:

Material Block:

Organization: Modify the search organization if necessary. If the field is left blank to view item quantity across organizations to which the access is provided to the user.

Subinventory: If subinventory is defined in this field from the LOV for the organization, the quantity for the item can be viewed. If the field is left blank then to view item quantity across organizations to which the access is provided to the user.

‘Show Disabled Subinventory/Locator in LOV’: Checkbox indicates whether the quantity in disabled subinventory / locator also to be displayed.

Locator: If locator is defined in this field from the LOV for the organization & subinventory, the quantity for the item can be viewed. If the field is left blank then to view item quantity across organizations to which the access is provided to the user.

View By: Select how to view the query results. The available choices are:

Location

Item

Cost Group

Status

LPN (This option is available if Oracle Warehouse Management enabled organization)

Serial

Lot

Grade

Material Location Block:

Optionally, enter a material location. The available choices are:

On-hand: This material currently resides in a storage subinventory.

Receiving: This material resides in a receiving subinventory.

Inbound: This material is en route to the warehouse.

Note: If you select Inbound as the material location, you can view by location only.

The below table shows the search restrictions that apply the selection combination of material locations:

Tab

|

On-Hand

|

Receiving

|

Inbound

|

Item

|

Yes

|

Yes

|

Yes

|

Lot

|

Yes

|

Yes

|

Yes

|

Serial

|

Yes

|

Yes

|

Yes

|

LPN

|

Yes

|

Yes

|

Yes

|

Project

|

Yes

|

No

|

No

|

Consigned / VMI

|

Yes

|

No

|

No

|

Interorg

|

No

|

No

|

Yes

|

Supplier

|

No

|

No

|

Yes

|

Item Tab:

Item / Revision: This is the item and revision number.

Note: If multiple material locations selected, then you must enter an item.

Description: This is the item description that is defined in the Item Master. This field is populated automatically when the item number is entered.

Item Cross References: This is the item cross-reference designation.

Cost Group: This is the cost group that is associated with the item. You can enter cost-group information only if the org is an Oracle Warehouse Management enabled organization.

Status: This is the item material status.

Lot Tab:

Lot From / Lot To: These fields determine the range of lot numbers on which is to be searched.

Lot Context: This is the lot context to be searched. Lot contexts are item flexfields that are defined. You can search on lot context only if the org is an Oracle Warehouse Management enabled organization.

Lot Attributes: This is the attribute of the lot on which it is to be searched, for example, lot expiration action.

Grade: This is the lot grade on which it is to be searched for example, good, poor, or average.

Expired Lots: Select this check box to search for all lots that have expired as of the date that specify in the adjacent Expiration Date field. When the Expired Lots check box is enabled, the system date appears by default in the Expiration Date field.

Serial Tab:

Serial From / Serial To: These fields determine the range of serial numbers on which it is to be searched.

Serial Context: This is the serial context on which it is to be searched. Serial contexts are item flexfields that is defined. You can search on serial context only if the org is an Oracle Warehouse Management enabled organization.

Serial Attributes: These are the attributes of the serial number on which it is to be searched.

LPN Tab:

LPN From / LPN To: These fields determine the range of LPNs on which it is to be searched

LPN State: This is the current state of the LPN on which it is to be serached . Examples include Resides in Inventory and Loaded for Shipment.

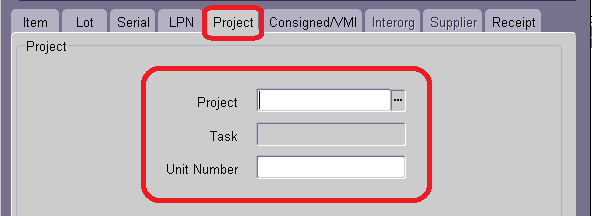

Project Tab:

Project: The project number for which to find the material.

Task: The task for which to find the material.

Consigned / VMI Tab:

Owning Party: Optionally, select from the following owning party options.

All Owning Parties: This option enables to search for material for all owning parties.

All Consigned Stock: This option enables to search for all consigned stock.

Select Owning Party: This option enables to specify an owning party, and searches only for material the owning party owns.

Planning Party: Optionally, select from the following planning party options.

All Planning Parties: This option enables to search for material for all planning parties. All VMI Stock: This option enables to search for all VMI stock.

Select Planning Party: This option enables to specify a planning party, and searches only for material that is associated with that planning party.

Interorg Tab:

Source Org: This is the shipping organization. The system considers the current organization the destination organization.

Requisition Number: This field displays the internal requisition number. The list of values displays all requisitions for the destination organization. If you enter a source organization, then the list of values displays only requisitions that match the source organization that you entered, and the current organization.

Shipment Number: This field displays the shipment number for the inter-organization transfer. You cannot enter a shipment number if you do not enter a source organization.

Internal Order: This field displays the internal order number. You cannot enter an internal order number if you do not enter a source organization.

Expected Receipt Date: This field displays the expected receipt date for the purchase order, ASN, inter-organization shipment, or requisition.

Supplier Tab:

Supplier Name: The name of the supplier from which you receive the material.

Site: The supplier location that shipped the material.

Purchase Order: The purchase order number.

Include Orders without ASNs: If you select this check box, then the system includes orders for which you did not receive ASNs in the inbound material query. The system uses the promise date to determine the arrival of the inbound material. If you do not select this check box, then the system includes only ASNs in the inbound material query.

Release Number: The blanket purchase agreement release number. You can enter a value in this field only if you entered a PO number in the Purchase Order field.

ASN: The ASN number you received that indicates an inbound shipment is intransit to the warehouse.

Vendor Item: This is the supplier internal item number.

Expected Date: This field displays the expected receipt date for the purchase order, ASN, inter-org shipment, or requisition.

Receipt Tab:

Receipt: The receipt number for the delivery transaction.

Material Workbench: Display Options:

The viewing option will be based on the selection & the options are:

Location

Item

Cost Group

Status

LPN

Serial

Lot

Grade

Material Workbench: On-hand – Availability:

Click Availability.

The following information will be displayed in the Availability window:

Material Location: The item material location.

Organization: Organization where the item resides.

Item / Revision: The item and revision number.

Subinventory: Subinventory within the organization where an item resides.

Locator: Row, Rack & Bin where the item resides.

Lot Number: Item lot number if the item is under lot control.

Serial Number: Item serial number if the item is under serial control.

Grade: Lot grade if the item is under lot and grade control.

Cost Group: Item cost group.

Primary On-hand: Number of items that are available in the subinventory in the primary UOM.

Secondary On-hand: Number of items that are available in the subinventory in the secondary UOM.

Primary Available to Reserve: Available quantity of an item that you can reserve across an organization in the primary UOM.

Secondary Available to Reserve: Available quantity reserve across the organization in the secondary UOM.

Primary Available to Transact: Available quantity of an item that you can transact across an organization in the primary UOM.

Secondary Available to Transact: Available quantity of an item that you can transact in the secondary UOM.

Innermost LPN: The LPN within a subinventory where an item resides.

Note: This field appears only if the org is a warehouse management enabled organization.